Home • Our Processes

Our Processes

At OCM, precision and consistency are built into every step of our manufacturing process. From raw material sourcing to final inspection, we combine skilled craftsmanship with advanced technology to ensure each product meets the highest standards of quality, performance, and reliability.

Mill-Direct Steel Purchasing

We source our steel directly from trusted mills, ensuring consistent quality, better pricing, and full traceability. This direct purchasing model allows us to maintain strict material standards while passing cost efficiencies on to our customers.

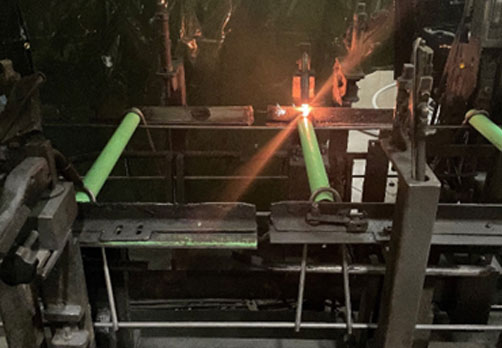

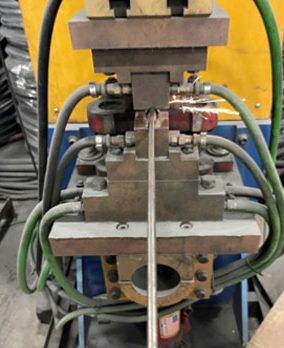

Welding

Our in-house welding operations ensure strength, precision, and consistency across every product we manufacture. With precision welders and quality-controlled processes, we’re able to meet demanding specifications for both standard and custom components.

Two Epoxy Coating Lines

With two dedicated epoxy coating lines, we deliver superior corrosion resistance and durability across a range of products. Our in-house coating capabilities allow for consistent quality, fast turnaround times, and the flexibility to meet specialized project requirements.

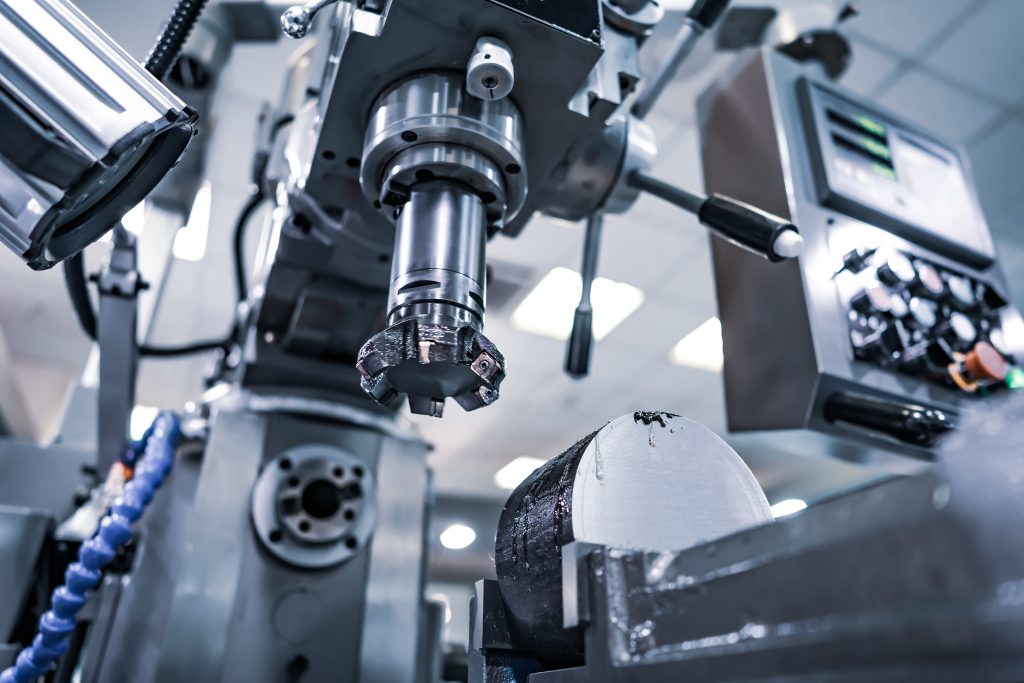

Stamping

Our precision stamping capabilities allow us to produce high-volume metal components with exceptional accuracy and repeatability. From standard parts to custom designs, our stamping process supports a wide range of construction applications with consistent quality and tight tolerances.

Plastic Dipping

Our plastic dipping process adds a durable, protective coating to metal components, enhancing grip, corrosion resistance, and overall performance. This in-house capability allows us to deliver high-quality, job-ready parts that meet both functional and aesthetic standards.

3D Bending Capability

Our advanced 3D bending technology allows us to form complex shapes and angles with precision and efficiency. Ideal for custom and high-performance applications, this capability enhances our flexibility in meeting unique design requirements across a variety of construction products.

Cutting & Straightening

Our in-house cutting and straightening operations ensure precise lengths, clean finishes, and consistent results for wire and rod-based products. This capability supports both standard production and custom orders, helping us meet tight tolerances and fast lead times.

Expanded 3D Bending Capabilities

We’ve enhanced our 3D bending capabilities to offer greater flexibility, tighter tolerances, and faster turnaround times. This expansion allows us to take on more complex designs and higher production volumes while maintaining the precision and consistency our customers expect.

American-Made Products Available

American-Made Products Available