The need for more energy efficient construction has guided the precast concrete industry into designing more cost effective and energy efficient precast wall panels that can be produced more efficiently. Recent federal and state regulations have driven the industry to develop better and more efficient precast “sandwich panels” which utilize a middle layer of insulation sandwiched by two layers of concrete.

OCM now offers Welded Wire Girder to meet the needs of “sandwich panel” construction. It is designed to properly transfer and distribute the loading to the different wythes of the sandwich panel, therefore eliminating the need for any solid sections between the wythes and eliminating thermal bridging. OCM Welded Wire girder connects the wythes through the insulation, and it has the resiliency to expand and contract with the independent thermal induced movements of the outer wythe. Welded Wire Girder will help prevent the issues of high stress points, thermal areas, cold spots, and wet areas on the interior wythes.

Features:

- Cost effective and energy efficient.

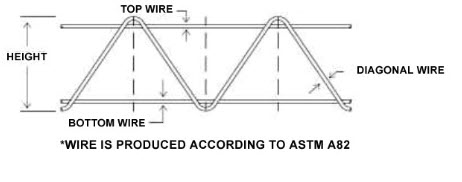

Top Wire:

| Maximum Size |

Minimum Size |

| 0 Gauge (.306″ diameter) |

4 Gauge (.225″ diameter) |

Bottom Wire:

| Maximum Size |

Minimum Size |

| 0 Gauge (.306″ diameter) |

4 Gauge (.225″ diameter) |

Diagonal Wire:

| Maximum Size |

Minimum Size |

| 3 Gauge (.243″ diameter) |

6 Gauge (.192″ diameter) |

Height:

- Minimum size is 3″ to 9″ maximum in incremental change in height of 1/2″.

Length:

- Standard Lengths are 10′ and 12′.

- Available with Mill Galvanized Wire.

Installation:

- Install bottom wythe mesh and place single girder into form, then tie it to the mesh or prestressed cables.

- Pour bottom wythe of concrete, raise or rotate single girder to a vertical position such that 2/3 of the girder height is standing out of the concrete.

- Install insulation board in strips between the girder and walk along the insulation board, pressing the insulation board in and around the girder diagonal wires.

- If any gaps or spaces occur, tape or caulk gaps to prevent any concrete or thermal bridging between the top and bottom wythes.

- Install top wythe mesh and tie to girder or to prestressed cables for support and proper positioning in center of top wythe. Then place remaining concrete.

American-Made Products Available

American-Made Products Available